New products are being developed at an increasing rate, and many older products are still in operation and continue to be for many years. This implies heavy training needs especially for new employees. The need for a knowledge base that would help retain existing knowledge from the old experts was apparent, and when Liebherr-Mining evaluated different software tools, they found Dezides causal AI technology to meet their needs.

Liebherr Mining Equipment retains knowledge as the workforce increases

As the field service technician workforce is growing and younger generations are being hired, Liebherr-Mining was facing considerable increases in training programs to keep up with service demands.

Reduced Troubleshooting Time

Retention of Existing Knowledge

New Business Opportunities

About Liebherr Mining Equipment

Since 1961, Liebherr has produced hydraulic excavators in Colmar, France. Along with earthmoving, demolition, and other industrial products, Liebherr also offers machines for the extraction and loading of material in the open-cast mining industry. Liebherr-Mining excavators are used in all surface mining applications for extracting gold, diamonds, platinum, coal, iron ore, copper and much more. Liebherr Mining Equipment Newport News Co. in Virginia, USA, has been manufacturing large mining trucks for mining industry since the mid-1990s. These trucks are specifically engineered for use in high-production sites in extreme climates and operate in a variety of worldwide mining applications.

Training Needs Were Escalating as The Aging Workforce Was Being Replaced by Younger Technicians

Liebherr recognized that without a solution, they would have to increase training time of the field service technicians considerably and they would have been forced to create specialists for each family of machine or technology to make sure they could continue to deliver support for those machines.

This would greatly influence the number of technicians and the flexibility to send them to various missions. The management of highly specialized technicians only capable of working on certain types of machines becomes impossible when service and support are performed in all the remote corners of the world.

It had become mandatory to train technicians to be able to work on many different machines and many different technologies. The multi-skilled technicians would allow Liebherr to be more reactive and more flexible in a field where the machine technology and product range have very quickly evolved to answer the needs of the market and also the rise of the new emerging countries.

Another crucial factor is the fact that many former product models are still in operation and have been produced many years ago and will remain in operation for many years to come. Combined with an extensive range of mining machines including trucks, excavators, and dozers, the training requirements for new as well as old technicians was quickly increasing.

Furthermore, the traveling technicians are becoming younger and younger, because this difficult trade is only done for a number of years before it gets too hard. This implies that some technicians have to troubleshoot machine types they have never seen before and don’t know the particulars about.

The decision to go with Dezide

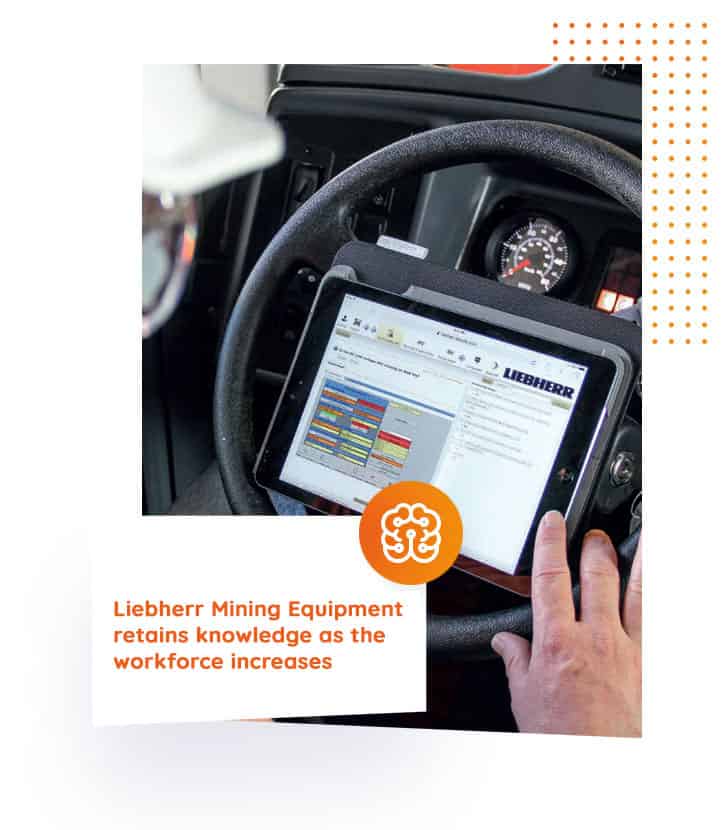

Rigorous test and benchmarks were performed for the various software solutions that were being evaluated. Tests were performed in the factory where a number of errors were introduced into a machine and the engineers should find and fix these errors with and without using the Dezide tool.

On selected errors like “Relay broken” and “Fuse blown out” the reduction in handling time was impressive with troubleshooting time reduced by an average of 60%.

A project manager led the study of the needs and the market of the existing tools, the technologies used and the implementation processes. This project is managed entirely by the after-sales service department, which determined that the causal AI troubleshooting capabilities offered by Dezide matched Liebherr’s requirements.

Dominique Ehrhardt continues:

… and probably the most important, we valued the close contact with Dezide, their responsiveness to our requests and their support.

Implementation & Operational model

From initial pilot project to full support for all products, the process took over three years to be implemented and roll out to all technicians. The intentional long project plan was organized that way to create the maximum sustained success of the tool, as introducing new IT tools to technicians had historically proven to be difficult.

Liebherr decided to build the entire knowledge base including dynamic guides, static guides, and articles for one type of machine (the very popular R 9250 excavator) and then roll out to a defined number of users in order to get their feedback and to learn and improve for the next round with a wider audience. Getting people involved in the project early on was the key to the success of the tool.

Liebherr has one project manager and two knowledge base editors. The project manager is the contact to Dezide, the marketing department, the IT department and to the end user manager. He is also responsible for defining the design and layout of the tool according to the Liebherr design policy. The knowledge base editors build and maintain the guides and articles and they also handle incoming feedback from the users containing updates and suggestions for the knowledge base.

Intelligent Service Solutions Strengthens Customer Relations

In the service business, Liebherr has seen the business benefit in making the knowledge base a part of the service offering for customers. This means, that Liebherr is capitalizing on their knowledgebase by selling access to restricted parts of it to customers who want to perform troubleshooting on their own using their own people.

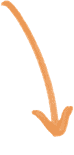

Liebherr has branded the customer-facing Dezide solution as the “Liebherr Troubleshoot Advisor”. The product page can be seen here:

You can see the product presentation video to the right ->

Liebherr Mining Equipment Retains Knowledge using Dezide

Liebherr Mining has transformed the after-sales service department going from unstructured knowledge and heavy training times to being very effective at handling retention of existing knowledge. The challenge of deploying captured expert knowledge to the hands of all field service technicians has been addressed efficiently, and Dezide is now used by the customer service team worldwide.

For Liebherr, retaining and transferring tribal knowledge to the next generation and making sure all technicians can solve problems on multiple machine types, knowledge management is playing a more critical role than ever and the positive impact on customer service and technician training is impressive.